5 Minute read

A small, lightweight device that can detect and identify hazardous and greenhouse gases in the field using infrared spectroscopy has been developed. It is based on research conducted at the University of Melbourne and developed in partnership with Innovative Protection Solutions Pty Ltd and the Defence Science and Technology Group.

Key points

- A portable infrared spectrometer has been developed for the on-site detection of various chemicals, including hazardous gases

- This device can swiftly identify chemicals, thanks to the advanced infrared metasurface it houses

- Commercialisation of a portable IR spectrometer has the potential to improve safety across a variety of industries, including chemical manufacturing, food production, pharmaceutical manufacturing, environmental monitoring and defence

- The technology is developed by the University of Melbourne, in collaboration with Innovative Protection Solutions Pty Ltd (IPS) and the Defence Science and Technology Group (DSTG).

The outcome

A new, portable device that could revolutionise hazard detection is under development at the University of Melbourne. The project is led by Professor of Physics and Electronic Engineering, Ken Crozier, an expert in nano and micro-optics, and ultra-thin detection systems.

“We have developed a miniature infrared spectrometer based on optical metasurfaces and machine learning that can have many applications,” Professor Crozier says.

The small, lightweight device can detect hazardous and greenhouse gases, including methyl-ethyl-ketone, ammonia, carbon dioxide and methane. It can also be used on liquids and solids, with great potential for Australia’s defence and civilian industries where sensing capabilities are crucial for protecting against chemical threats and exposure. Integration with machine learning software allows users without training in infrared spectroscopy to identify chemicals present.

The next step is designing a production process – which is where the commercial partner IPS comes in. IPS is a joint venture between Memjet and Flame Security International.

Memjet is an Australian company that works with sensor technologies in the defence space. Their expert advice helped redesign the device as more rugged, smaller, and better suited for the application.

Flame Security International creates innovative solutions to protect people, structures and the environment from fire and other threats, including the development of early warning technology. They contribute extensive understanding of defence and fire protection markets.

The need

Many methods to identify chemicals from a very small sample use laboratory benchtop tools like Fourier transform infrared spectrometers – equipment that is usually expensive and bulky, typically weighing several kg or tens of kg.

The price, heft and complexity of such tools means that detecting small amounts of gases (or liquids and solids) in the field using this method is often impractical. Recreating a portable, inexpensive version with comparable sensitivity to benchtop tools could revolutionise a range of monitoring applications.

Potential applications include detecting harmful gases in industrial settings, where infrared sensors could monitor air quality, triggering an alarm if gas concentrations such as methane increase beyond a certain level.

Portable IR spectrometers could also be used in:

- Food production to detect contaminants, preventing food poisoning

- Pharmaceutical manufacturing to detect impurities in drugs

- Medical diagnostics, where certain disease molecules (including some cancers) can be detected with infrared spectroscopy.

In defence and security, infrared sensors could improve safety by detecting dangerous materials like toxic industrial chemicals, while allowing industry workers and first responders to be at a safe distance and not exposed to harm.

Developing the solution

Infrared spectrometers can detect and identify gases and molecules invisible to the naked eye by using unique absorption patterns.

“The mid-infrared is perfect for our application, because nearly all solids, liquids and gases absorb very specific frequencies in this wavelength range,” Professor Crozier says.

To identify specific molecules in a sample, infrared light is sent through a sample of molecules, then the wavelengths coming out the other side are measured.

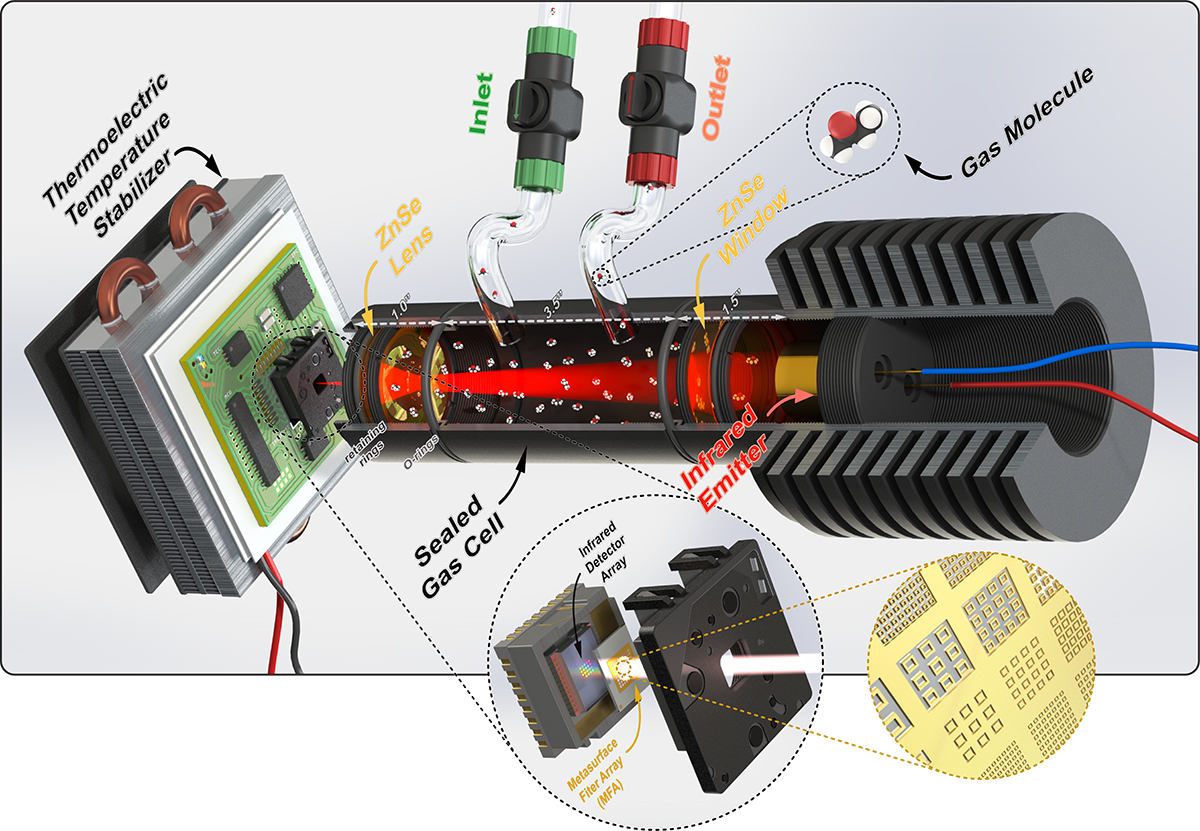

The team has developed a ‘compact chemical identifier’, a portable infrared spectrometer platform made up of an infrared light source, an aluminium miniaturised measurement chamber into which the gases are introduced, and the metasurface integrated into a lightweight thermal camera.

Light from the infrared light source passes through the tube, with certain wavelengths being absorbed by the gas molecules. The combination of the metasurface and thermal camera allows the transmitted light – light not absorbed by the molecules – to be analysed. The data collected is then processed by machine learning software that reports which gas is present.

Industry collaborator IPS has access via its shareholders to market-leading technology in digital printing, electronics design, material testing, robotic assembly, and toxic chemical sensors which include applications for defence customers. DSTG is providing expert advice on the latter, especially related to capability gaps of current technologies.

IPS has direct access to services that include product development through to establishing manufacturing systems, including fully automated robotic assembly lines which allow cost-competitive manufacture in Australia. The company is also a technology supplier for CBRN (chemical, biological, radiological and nuclear) devices for Australia’s Defence Science Technology Group.

“Our extended team via the IPS joint venture includes specialists in aerodynamics and microfluidics, we have physicists, chemists, both organic and inorganic, and every engineering discipline other than civil; we have manufacturing clean rooms and access to some of the world's largest foundry partners,” says IPS CEO Jason Thelander.

Partners

IPS Joint Venture Partners (Memjet Australia and Flame Security)

Defence Science and Technology Group, Australia

Funding support

This work was supported in part by the Department of Defence’s “Operating in CBRN Environments” STaR Shot and the Defence Science Institute, under the Hazardous Agents Challenge. The Defence Science Institute is an initiative of the State Government of Victoria.

This work was supported in part by the Australian Research Council (ARC) Centre of Excellence for Transformative Meta-Optical Systems (TMOS, CE200100010).

This work was performed in part at the Melbourne Centre for Nanofabrication (MCN) in the Victorian Node of the Australian National Fabrication Facility (ANFF). It was supported in part by the MCN Technology Fellow Ambassador program.

First published on 7 September 2023.

Share this article

Keep reading

-

Explore more Defence research

Research that enhances the safety of all Australian personnel and enables national defence systems to meet an increasingly complex security landscape.

-

Why partner with us

Partner with the University of Melbourne. Join a community where the world’s best minds help solve the biggest global challenges of our time.

-

Collaborate with us

Explore some of the many ways you can partner with us to help your organisation excel.

-

Nanosatellites expedite satellite intelligence

The Melbourne Space Laboratory develops solutions and payloads for nanosatellites, enabling applications traditionally restricted to larger satellites.