4 Minute read

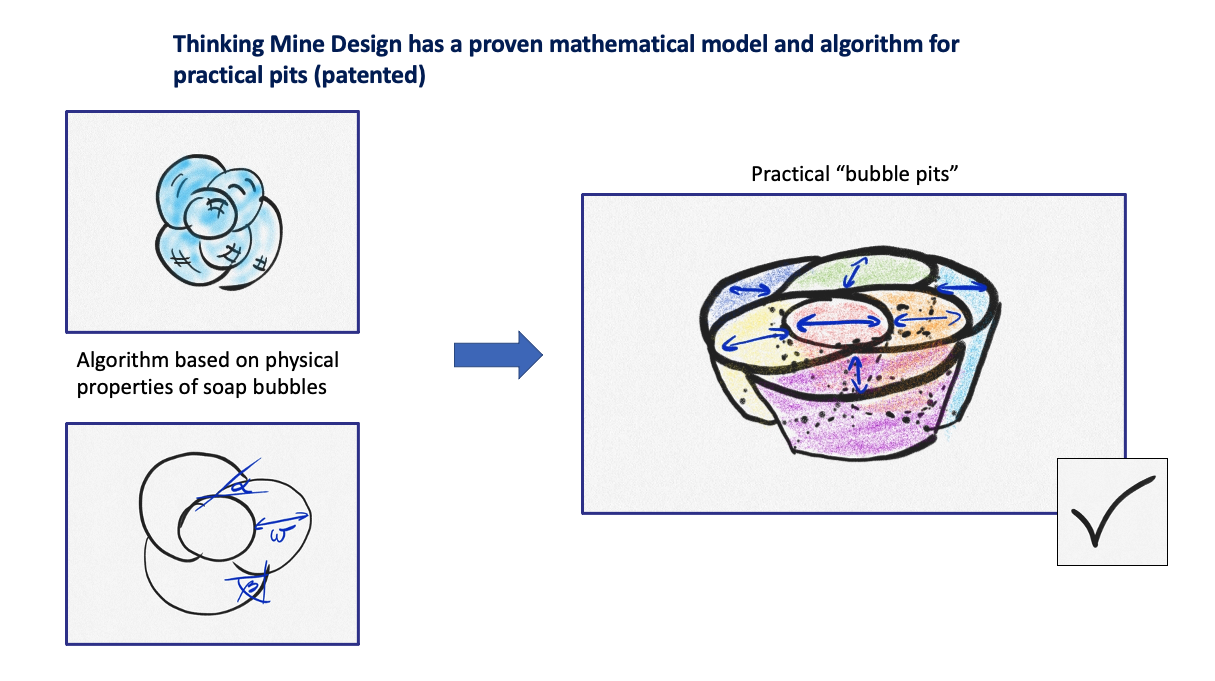

Using an algorithm based on the physical properties of soap bubbles, researchers at the University of Melbourne have developed software to solve operational issues that have not been implemented in traditional approaches to open pit mine design.

Key points

- BubblePit software optimises open-cut mine design to improve operational efficiency

- The software uses the first commercially available algorithm to account for the complex geometrical constraints of pushback design

- Benchmarked against leading industry software, BubblePit delivered better value and more mineable pushbacks

- A direct block scheduling version of the software has also been developed

- The algorithm was developed by researchers at the University of Melbourne.

The outcome

Miners will now be able to optimise the value of ore they are able to extract from open-cut mines using software developed by University of Melbourne researchers through their start-up company, Thinking Mine Design.

The software designs pits in nested clusters that provide connectivity and minimum bench width needed for equipment access.

“It is the first commercially available algorithm that accounts for the complex geometrical constraints of pushback design,” says Professor Hyam Rubinstein.

The changes to the way open-cut mines are designed could support values of between 5 and 15 per cent greater than previous pit construction allowed, depending on the complexity of the design.

“Leading mining companies have tested the software extensively on real data sets,” says Professor Rubinstein.

In benchmarking tests against a leading industry software provider, BubblePit delivered better value and more mineable pushbacks.

An extension of the software, BubbleSched, is a direct block scheduler – dividing up pits into a mining production schedule for the ore blocks – that includes the mineability constraints of BubblePit.

In benchmarking, direct block schedules obtained with BubbleSched were close to optimal. Moreover, the set of blocks selected for each mining period by BubbleSched, satisfy the operational constraints of minimum mining width and connectivity. Currently available commercial solvers are unable to incorporate these constraints into the optimisation of schedule value.

The need

Large-scale mining of primary resources presents a range of complex challenges. Companies have been investing heavily in finding ways to make mining more cost-effective and efficient.

Open-pit mining is the most common method used to excavate ore deposits that are relatively close to the surface of the earth.

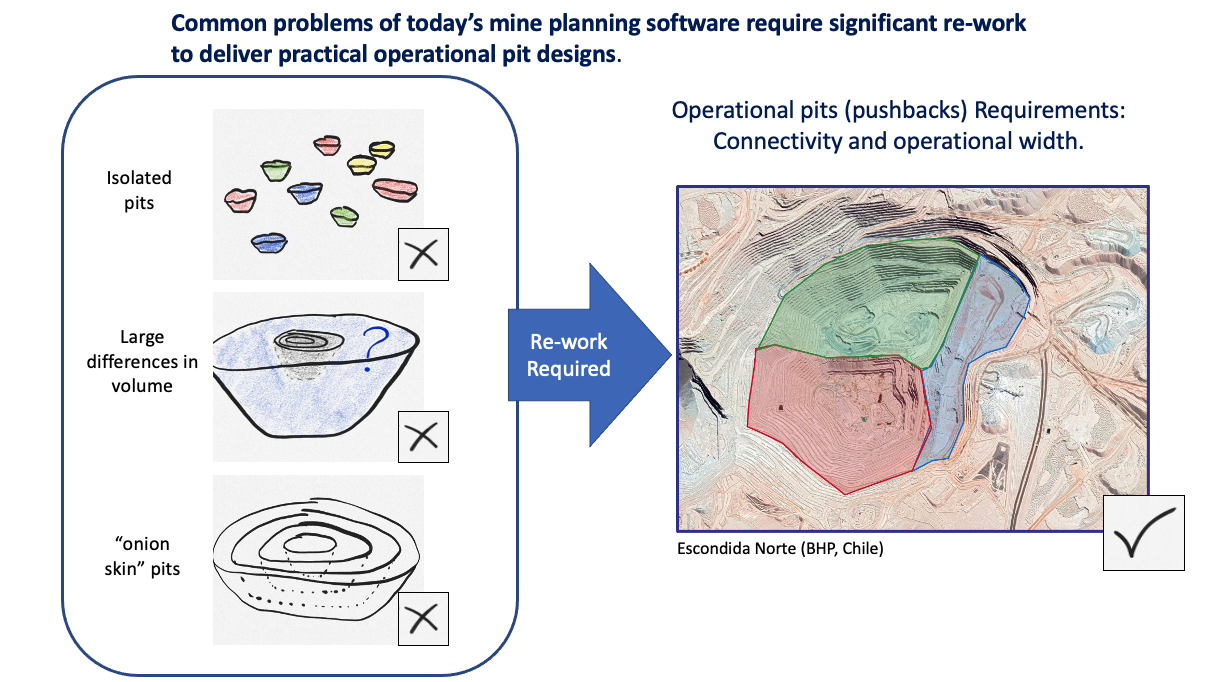

“For decades, the industry has been trying to find a way of incorporating geometrical constraints of the shapes of the pits into the design process, in order to maximise value and satisfy operational needs,” Professor Rubinstein says.

Traditionally, open-pit mines have been built through a series of nested pits, known as pushbacks, leading to the easily recognisable terraced pits found in mines throughout the world.

Since the upfront investment in establishing mines is so significant, it’s also important to maximise the efficiency of scheduling and haulage.

![]()

Developing the solution

Software developed by mathematician Professor Hyam Rubinstein and mining engineer Dr Juan L. Yarmuch can be used to address the problems that have faced the industry for many years.

The BubblePit software uses the geometric properties of masses of soap bubbles to find the optimal design shape for the nested pits.

Key ideas for this project were developed during Dr Yarmuch’s University of Melbourne PhD, which was co-supervised by Professor Rubinstein.

After receiving a grant through AMIRA Global, the BubblePit software was completed in July 2021. The software development was supported by Australian’s Newcrest Mining and Newmont Mining, the world’s largest gold mining company. Both Newcrest and Newmont have trialled the software in their mining operations. Leading global mining company Rio Tinto also extensively tested an early version of the software.

Funding

AMIRA Global with sponsors Newcrest and Newmont for both BubblePit and BubbleSched.

Patents

Mine Planning method and system. Inventors: J.H. Rubinstein, J.L. Yarmuch. Patent numbers: CA3100082A1, PE20201442A1, US20210208305A1, CL2020003055A1, BR112020024085A2.

Mine planning method and system

The background Intellectual Property (IP) is owned by the University of Melbourne through a patent and Thinking Mine Design has an exclusive agreement with the University of Melbourne for commercialisation of the IP.

Publications

J. L. Yarmuch, M. Brazil, J. H. Rubinstein, D. A. Thomas, Optimum Ramp Design in open pit mines, Computers and Operations Research, 115, (2020) https://doi.org/10.1016/j.cor.2019.06.013

J. L. Yarmuch, M. Brazil, J. H. Rubinstein, D. A. Thomas, A mathematical model for mineable pushback designs, International Journal of Mining, Reclamation and Environment, (2021), 1-17 https://doi.org/10.1080/17480930.2021.1885582

J. L. Yarmuch, M. Brazil, J. H. Rubinstein, D. A. Thomas, A model for open-pit pushback design with operational constraints, Optimisation and Engineering, Nov. 2021 DOI https://doi.org/10.1007/s11081-021-09699-9

People

Professor Hyam Rubinstein, School of Mathematics and Statistics, University of Melbourne

Dr Juan L. Yarmuch, Assistant Professor, Department of Mining Engineering, Universidad de Chile

Banner image: Picture: Getty Images

Keep reading

-

Why partner with us

Partner with the University of Melbourne. Join a community where the world’s best minds help solve the biggest global challenges of our time.

-

Collaborate with us

Explore some of the many ways you can partner with us to help your organisation excel.

-

Torch Recruit

The University of Melbourne is collaborating with regional and rural GPs across the country to improve health outcomes, with the help of an innovative new platform.

-

Improving business performance using process-mining software

Apromore, a University of Melbourne start-up, has raised $A6.84 million for commercial development of its open-source process-mining software.